Folding Disc Harrows

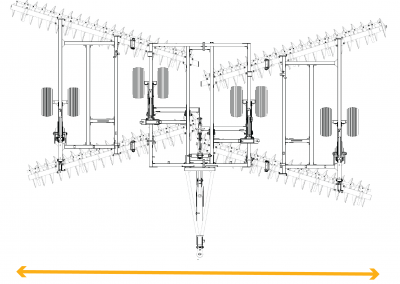

The F15 Double Offset Tandem Disc Harrow utilizes folding flexwings to follow the contour of the field and a double offset tandem design to smooth the soil. Overlapping front discs cut through soil and residue, while the flow of soil off the staggered rear disc gangs fills in the center furrow. This results in a more even performance and the perfect seedbed—without the need for a shank to level off the center.

Use the F15 for primary or secondary tillage, seedbed prep, or incorporation of chemicals. Turn it loose in your heavier primary tillage situations or to incorporate residue—including residue from cover crops—for faster breakdown.

We offer different models for a wide range of operations. All are field-tested and proven tough: 9″ spacing; 16’6″, 18’0″, 19’6″, 21’0″, 24’0″, 27’0″, 30’0″, 34’6″, and 39’0″ cutting widths.

Model shown above: F15B-6622

Folding Disc Harrow: F15B

F15B Workhorse

| Model | Cutting Width | Transport Width | Transport Height | No. of Disc Blades | No. of Bearings | Approx. Engine HP Required | Approx. Weight lbs.* |

|---|---|---|---|---|---|---|---|

| F15B-4622 | 16’6″ | 12’6″ | 9’6″ | 46 | 16 | 155-176 | 6,705 |

| F15B-5022 | 18’0″ | 12’6″ | 10’3″ | 50 | 16 | 162-189 | 7,419 |

| F15B-5422 | 19’6″ | 12’6″ | 11’0″ | 54 | 16 | 169-203 | 7,693 |

| F15B-5822 | 21’0″ | 12’6″ | 11’9″ | 58 | 16 | 182-223 | 8,346 |

| F15B-6622 | 24’0″ | 12’6″ | 12’6″ | 66 | 20 | 202-243 | 9,306 |

*To calculate weight per blade on each unit, divide the approximate weight by the number of blades.

Specifications subject to change without notice.

- Disc gangs feature maintenance-free bearings with three-year warranty; bearings eliminate possibility of contamination and need for re-lubrication

- Features 1½” square gang bolt

- Standard 22″ disc blades with 9″ blade spacing and welded steel spacer spools

- At 122 to 140 pounds per blade, the F15B offers excellent soil penetration

- Equipped with ³⁄₁₆″ x 6½″ x 8″ high-carbon steel, replaceable, adjustable scraper blades mounted on bars of 2½″ x 2½″ square tubing; the scrapers are attached to the 2½″ x ½″ thick arms with heavy-duty U-bolts

- Preset gang angle at 17º; no adjustment necessary

- Overlapping front disc blades give 100% tillage across the unit

- Offered in cutting widths from 16′6″ to 24′0″

- Weighs 6,705 to 9,306 pounds

- Folds to transport width of 12′6″ for easier road transport

Folding Disc Harrow: F15

F15 Heavy Duty

| Model | Cutting Width | Transport Width | Transport Height | No. of Disc Blades | No. of Bearings | Approx. Engine HP Required | Approx. Weight lbs.* |

|---|---|---|---|---|---|---|---|

| F15-6624 | 24’0″ | 14’6″ | 11’0″ | 66 | 20 | 230-275 | 11,591 |

| F15-7424 | 27’0″ | 14’6″ | 12’0″ | 74 | 22 | 243-297 | 12,283 |

| F15-8224 | 30’0″ | 14’6″ | 13’3″ | 82 | 22 | 256-318 | 12,935 |

NOTE: 15″ x 10″ 8-hole wheels and 8-hole hubs optional on 66-blade, 74-blade, and 82-blade models (center section only).

F15 Giant

| Model | Cutting Width | Transport Width | Transport Height | No. of Disc Blades | No. of Bearings | Approx. Engine HP Required | Approx. Weight lbs.* |

|---|---|---|---|---|---|---|---|

| F15-9424 | 34’6″ | 17’6″ | 14’0″ | 94 | 26 | 310-378 | 15,423 |

| F15-10624 | 39’0″ | 17’6″ | 15’9″ | 106 | 30 | 337-405 | 16,671 |

NOTE: 15″ x 10″ 8-hole wheels and 8-hole hubs standard equipment on 94-blade and 106-blade models (center section only).

*To calculate weight per blade on each unit, divide the approximate weight by the number of blades.

Specifications subject to change without notice.

- Disc gangs feature maintenance-free bearings with three-year warranty; bearings eliminate possibility of contamination and need for re-lubrication

- Features 1½” square, cold-rolled, high-carbon steel axles

- All models feature smooth blades with three step-down blades on the rear gangs; blade sizes are 22″ x ¼″, 24″ x ¼″, or 26″ x ¼″, depending on model and options chosen; notched blades are optional in all sizes

- Three diminishing blades on the outside rear gangs of the double offset tandem design achieve a berm-free, level seedbed with no additional tools required

- Equipped with ³⁄₁₆” x 6½” x 8″ high-carbon steel, replaceable, adjustable scraper blades mounted on bars of 2½” x 2½” square tubing; the scrapers are attached to the 2½” x ½” thick arms with heavy-duty U-bolts

- Hydraulic hoses complete to front of main frame

- 15″ x 10″ 8-hole wheels and 8-hole hubs are standard equipment on 94-blade and 106-blade models (center section only)

- 90″ tongue with jack enables sharper turns on dual-wheel tractors

- Features adjustable clevis of ductile iron with transport adapter

- Heavy-duty 3,000 PSI hydraulic cylinders adjust cutting depth and raise the disc for transport

- DIAL-A-DEPTH depth control allows an even cut with positive depth control the entire width of the harrow

Optional equipment:

- Shock Absorber Bearing Risers allow the gang on the harrow to travel up and down to relieve shock when the disc blades encounter an unexpected obstacle in the ground (available on all models)

- 15″ x 10″ 8-hole wheels and 8-hole hubs are optional on 66-blade, 74-blade, and 82-blade models (center section only)

- Hydraulic fore and aft cylinder for on-the-go field adjustments

Price Your Tillage Tool!